Air Handling Units

Air Handling Units

Univent, design, manufacture and install bespoke air handling equipment to suit all projects or client requirements. Our air handling units are manufactured utilizing closed cell anodized aluminium pentapost frameworks sized to suit the required panel and insulation thickness, each utilizing ‘knock in’ corner pieces.

Our air handling units can be manufactured with double skinned panelling and either a galvanised steel or leather grain plastisol coated Aluzinc outer skins (other materials & finishes are available on request) with inner skins normally incorporating galvanized sheet steel inner skins with options available for alternative materials or finishes to suit individual project requirements.

These skins would be formed into trays and would normally encapsulate a layer of mineral fibre insulation (thickness & density to suit client requirements). Air handling units for external applications incorporate weather proof roofs, inlet / discharge cowls or louvres & appropriate weather seals. Filtration would incorporate sufficient cells to suit the plant air flow in accordance with the stages & grades required.

Construction

- Frames: Extruded, anodised aluminium, closed section made as standard Plastic coated galvanised sheet steel (GSS), open section made as specials.

- Corners: Injection moulded ABS made as standard, cast aluminium made as specials

- Doors/Panels: Double-sided, nominal 25 or 50mm thick, fitted flush with frame. Outer skin, plastic-coated GSS as standard, GSS self finish made as specials. Inner skin, GSS as standard, plastic-coated GSS or stainless steel made as specials.

- Insulation: Thermal & acoustic minimum 60kg/m3 enclosed between panel outer and inner skins. Higher acoustic performance panels are available.

- Access Doors: Hinged plus key or clamped plus tool operated, to BS EN 292 Safety of Machinery.

- Bases: Full perimeter bolted, extruded anodised aluminium or folded GSS.Full perimeter welded, parallel side rolled mild steel channel painted or GAM.

- Roofs: Sloping, plastic-coated GSS.

- Skirts: Flared, plastic-coated GSS.

Components & Ancillaries

- Extract fans and drives. Vibration isolated, flexibly connected, raft or diaphragm plate mounted.

- Separation – mixing boxes. Weathering louvres, standard or acoustic.

- Shut off – volume control – non return – face and bypass dampers.

- Panel – bag – activated carbon – grease – absolute (H.E.P.A.) filters.

- Run-around coils – plate recuperators – thermal wheels – heat pumps.

- Heaters – coolers – humidifiers.

- Dagger plates for shut off during cleaning.

- Supply fans and drives. Vibration isolated, flexibly connected, raft or diaphragm plate mounted.

- Internal – external – one-two – multi or variable speed – duty and idling drives.

- Guards. Fan drive, inlet eye and discharge to customer requirements.

- Plenums – access – bend – diffusion.

- Atmosphere side – room side – zone attenuators.

- Unit is duct mounted. Side – end – central services corridors.

- Viewports – bulkhead lights and switches – nameplates.

- Inclined or dial gauge manometers.

- Floor grids – lifting beams. Heating and chilled water pipework and fittings.

- Refrigeration compressors, condensers, DX pipework, line fittings and controls.

- Refrigeration electrical controls and wiring.

- BMS compatible electrical controls – panels – interfaces – wiring – inverters – motor isolators.

- Support steelwork – side access platforms (made as specials).

- Simple and easy joining and sealing of component modules.

- All plant items. Slide in, slide out, bolt-in or bolt-on and are accessible and removable.

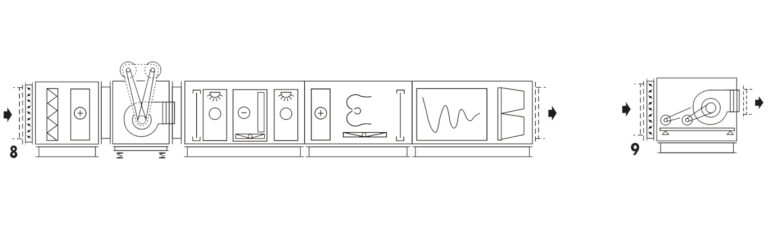

Popular Configurations